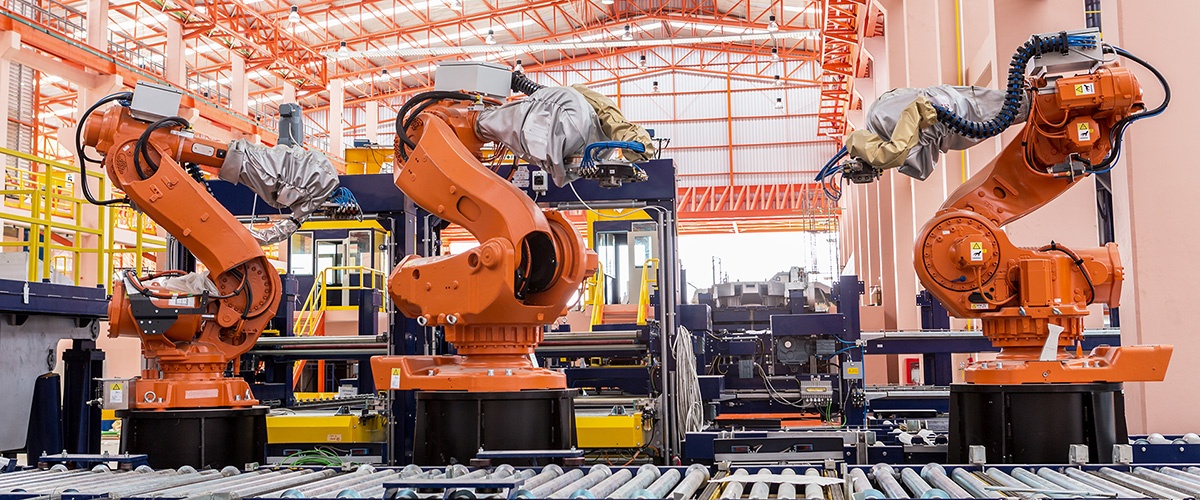

Competitive supply chains must enable a new level of coordinated performance that creates a high-fidelity picture of in-process flows across your extended network. Building the continuous supply chain supports contextual deviations, conveys alerts and drives continuous planning via sense & respond capabilities.

Optimizing multi-party business processes

Supply chains are complex networks where over 80% of the data and processes sits within partner systems. To see and act on the latest picture of your supply chain, your company needs that data from each of your partners, but the problem is most companies rely solely on an enterprise-centric approach to solve a multi-enterprise problem.

The only way to overcome those limitations is to adopt a "network approach." Connecting all partners to shared processes, data and metrics managed within a single platform creates a single version of truth for all parties. This allows supply chains to eliminate the data silos and inherent latency in order to reduce the root causes of friction, variability and costs in today’s supply chains, both internally and externally.

Read More

Topics: ERP, Manufacturing, Distribution, Rentals & Equipment, Supply Chain, Fashion & Apparel, Infor M3 ERP, Enterprise Software, Retail Supply Chain, WMS, Supply Chain Management

When every transaction counts more so than ever before in restaurants and food services, forward-thinking strategies around restaurant menu management have become more important than ever before. Central to that is how much leading organizations have risen to the occasion to streamline the way they manage they their offering and push the newest versions of menus to the point of sale, unified across locations and concepts.

Restaurants and managed food services rely on current data and the technology needed to find useful narratives about how to enhance performance and maximize returns, specifically at the menu item level. How does that work? What role does restaurant POS play in that process? Let’s take a look.

Read More

Topics: ERP, Food & Beverage, Distribution, Supply Chain, Food Technology, CloudSuite Food & Beverage, Enterprise Software

Many wholesale distributors tend to view warehouse operations as a cost center due to labor, equipment, physical inventory, and real estate investments. However, with business models rapidly changing through e-commerce, omni-channel engagement, and innovative services, warehouse operations that are re-imagined through investments in technology can empower a company to gain a competitive advantage. Streamlining and automating processes across the warehouse improve customer and employee experiences and inspire customer loyalty.

A recent article featured in Forbes highlighted survey-based research on practice, priority, and expectation trends of warehouse executives. Respondents chose a warehouse management system (WMS) as their highest priority for technology investment with 96 percent of survey participants noting that the warehouse automation value proposition was expected to increase over the next 3 years. Survey findings indicated that operational changes like labor costs, labor shortages, and increased throughput requirements were all primary factors for companies looking to automation.

Read More

Topics: ERP, Supply Chain, Warehouse Management Systems, Product Lifecycle Management, Infor M3 ERP, Enterprise Software, WMS, Supply Chain Management

Manufacturers in the food and beverage industry are increasingly turning to mergers and acquisitions to keep pace with consumer demands. In an era where speed is critical, many companies seem to find it to be faster and easier to form a partnership or make an acquisition, rather than invest in R&D or develop their own new products and brands from the ground-up.

The factors driving the trend

As economic recovery gains momentum and fuels a robust growth period in the food and beverage industry, expansion hungry manufacturers are eager to take advantage of new trends and the growing consumer obsession with the quality of the food they eat. Healthy snacks, plant proteins, clean labels, exotic taste experiences, neuro-nutrition, and socially mindful companies are all top-of-mind topics for today’s shoppers, especially millennials. Consumers now prioritize locally grown foods, sustainable farming, and organic and non-GMO foods, and are quite willing to read labels and research the origins of their meals, whether it be prepared in a four-star vegan restaurant or picked off the shelf of a corner convenience mart.

Read More

Topics: ERP, Food & Beverage, Supply Chain, Food Technology, CloudSuite Food & Beverage, Infor M3 ERP, Enterprise Software, WMS, Supply Chain Management

Food and beverage manufacturers rely on their R&D and marketing departments to develop new product ideas that capture market share before the competition can catch up. These departments leverage information available in their business systems to help them analyze trends ranging from buying patterns to cost fluctuations. The trouble is, when R&D and marketing rely on business systems that exist in silos— as is often the case with today’s food and beverage manufacturers opportunities are missed, product development is too slow, and costs creep higher. But when a manufacturer understands that every part of the organization has a stake in the product innovation process, and ensures that all the parts are connected, the organization is better positioned to deliver successful, innovative products quickly.

This white paper discusses a number of considerations that food and beverage manufacturers should make when examining ways to accelerate product innovation. This paper also details how digital technology can be the enabler of this acceleration.

Read More

Topics: ERP, Food & Beverage, Supply Chain, Food Technology, CloudSuite Food & Beverage, Infor M3 ERP, Enterprise Software, WMS, Supply Chain Management

The first place most organizations will go for answers to the remote work dilemma is into the arms of technology vendors. They will make the assumption that a new tool, or the enhancement of a current one will be the key to maintaining a productive workforce despite the continued existence of physical distance. After all, Zoom (arguably the most infamous beneficiary of the pandemic) went from 10 million daily users in December 2019 to more than 300 million in April 2020. In reality, there are sequential steps to take well before any new technology is introduced to the equation.

The culture question

The first step is more introspective, as organizations would benefit from a candid evaluation of their culture that may or may not be a strong foundation for a remote work environment. A dispersed workforce presents unique challenges that will quickly test the foundation of trust between employee and employer. Ryan Malone, founder of digital marketing agency SmartBugMedia finds this counterintuitive. "You've invested all of this time in vetting them," says Malone. "Why would you now say I don't trust you, because I'm not staring at you?” Would your organization be able to quickly adapt to this new degree of independence and autonomy, or would there be a temptation to revert to surveillance tactics to validate effort?

Read More

Topics: ERP, Fashion & Retail, Supply Chain, Fashion PLM, Cloudsuite Fashion & Apparel, Infor M3 ERP, Enterprise Software, WMS, Supply Chain Management

Fortunately, evaluations of the planning landscape reveal many organizations are adopting technologies that move towards a de-siloed, network-based approach to planning. For these companies, the primary goal centers around connecting planning capabilities to “a single version of the truth.” To optimize planning capabilities, it crucial to achieve this connection at the enterprise level as well as into the broader supply network.

But to do this involves using integrated business planning (IBP) or sales and operations planning (S&OP) to collaborate and analyze, perform demand planning to improve forecasting, optimize supply planning, and facilitate synchronization. Each of these areas are critical to a successful planning process and are more powerful when integrated and connected across a network.

Read More

Topics: ERP, Supply Chain, Product Lifecycle Management, Infor M3 ERP, Enterprise Software, Supply Chain Management

I recently posted on LinkedIn to ask my colleagues for advice on how to manage my exploding workload. According to the latest Mental Health Index: U.S. Worker Edition from Total Brain, between November and December there was a 48% increase in the risk of depression—a risk level not seen since this past spring. Further, employees’ focus dropped 62%—a record low since the inception of the research in February 2020. While remote working has its benefits, most of us would argue that we need to make some significant changes for this style of working to be sustainable. Below are a few of the suggestions and ideas from professionals that commented on the post.

Read More

Topics: ERP, Manufacturing, Food & Beverage, Distribution, Rentals & Equipment, Supply Chain, Fashion & Apparel, Infor M3 ERP, Enterprise Software, Retail Supply Chain, WMS, Supply Chain Management

The capabilities gap between older versions of ERP designs and current designs can create a problem that many organizations are slow to fix. If you already have an ERP system in place, but you’re running an older version of it, chances are your ERP is not helping your business to continue to grow and evolve as quickly as you would like. Changing vendors can be as expensive an endeavor as adding an ERP to your organization for the first time. But, if your ERP vendor has continued to make investments in their ERP solution, upgrading your current system—rather than replacing it—presents a very smart option.

Read More

Topics: ERP, Manufacturing

Do you have the data needed to determine cash investments, secure borrowing, and make better hedging decisions?

Today, financial services organizations are more focused on what’s necessary to safeguard business continuity and solvency. Much of this begins with greater visibility and reliability of key data to help drive your critical business decisions, especially during critical market changes.

Our current blog series is reviewing cash and treasury best practices you can follow to prepare for instant payments and build true cash visibility. The previous post discussed effective cash positioning and this week we focus on enhancing cash and liquidity forecasting.

Consideration #3: Enhance cash and liquidity forecasting

Treasurers don’t typically have access to a company’s full cash picture. Though efficient business operations require working with multiple financial services organizations across different markets, complex banking structures and sprawling geographical footprints make it difficult to achieve complete visibility into current balances and to measure the accuracy of cash forecasting.

Download the eBook

Cash and treasury: Prepare for instant payments and build true cash visibility

Read More

Topics: ERP, Distribution, Supply Chain, Enterprise Resource Planning, Cloudsuite Fashion & Apparel, Infor M3 ERP, Infor CloudSuite PLM for Fashion, Infor CloudSuite Fashion PLM, Enterprise Software, Infor CloudSuite Fashion, Supply Chain Management, Infor CloudSuite M3, Infor CloudSuite ERP

.jpg)

.jpg)